Description

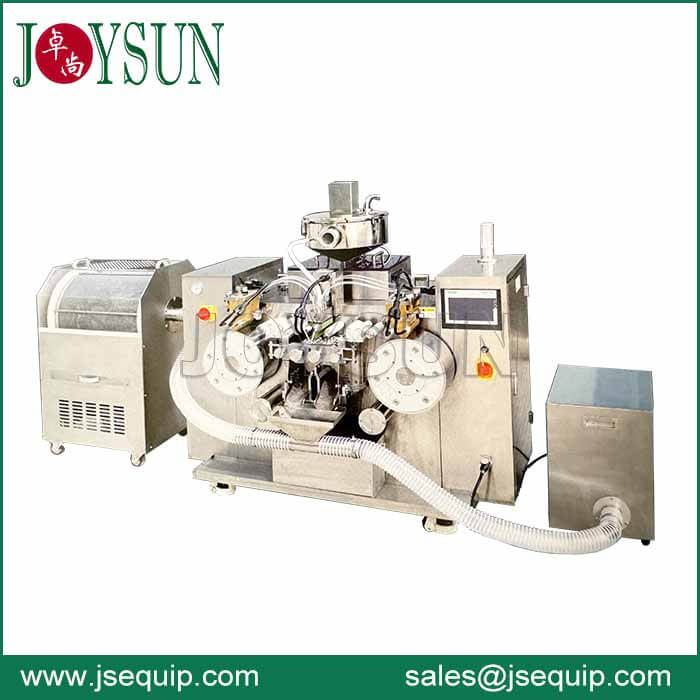

Softgel Polisher|Softgel Wiping Polishing Machine

Joysun has two types of softgel polisher as in polishing pan and tumbler polishing design. They are designed to polish softgel surface for a brighter and shining result. It mainly contains one barrel with well polishing technique.

Softgel Polishing Pan Type

The pan turns clock wisely and with speed control. When the polisher stops running, its discharge port will face vertically downward automatically, which makes capsule discharge easier. One electric box with all necessary safety protection can be customized on different countries’ voltage systems. Max. loading: <100kg per batch.

Softgel Polishing Pan Operation

1. Open the cover

2. Fill in soft gels

3. Throw several cotton wiping cloths in the pan

4. Close cover

5. Switch the rotating button, and the polishing process starts

6. During rotation, the capsule and cloth fully contact to soak the extra oil outside soft gels

7. After several minutes, stop the machine, and open the cover to check softgel (manually check whether the soft gel is ready or not, as different types of soft gels are covered with different amounts of oil, we cannot give a sure answer of how long it takes; for certain species, try 1 or 2 times, you will get the experience)

Tumbler Softgel Polisher

According to different customers’ needs, we also have a special Tumbler polishing design. Compared with softgel polish pan, it has below advantages:

It is easier to use, continuous forward and reverse rotation;

Less labor strength for softgel loading and unloading; automatic discharge.

Continuous batch running.