Description

Gummy Packing and Bag Forming Machine

Introduction

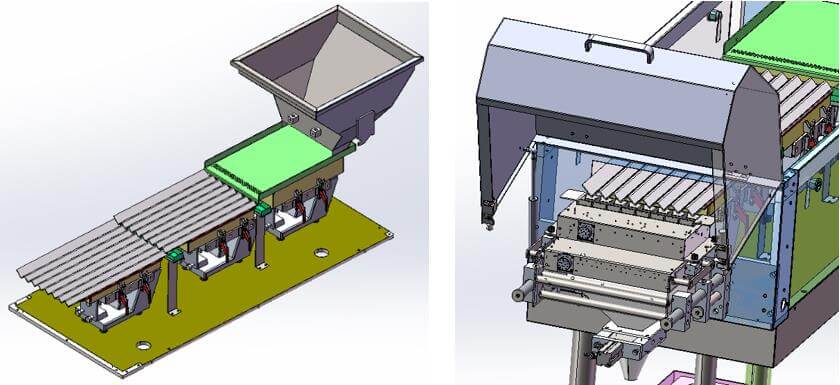

Gummy candies are countable and fillable into JS gummy packing and bag forming machine. This gummy packaging machine combines an electric counting filling function with a film bag-forming mechanism. Therefore, the gummy is measured by gummy pieces and not weight. The gummy packing and bag forming machine is not limited to just packing gummy, hard candies; it is also applicable for small solid objects such as tablets, softgel, capsules, pills and etc. This packaging machine is a stand-alone model which is also compatible with connecting to the automatic packaging line, and OKAY to respond to the MES system.

Gummy Packing and Bag Forming Machine Features

- Accurate: Adopting an independent optical detection system to ensure a high level of counting accuracy and speed; The smallest identified size: 1mm.

- Fast: High-speed counting speed. the counting efficiency can reach up to 20,000 pcs /minute if it is for gummy candy. For metal material, the speed is even higher.

- Flexible: With one-key cleaning and quick switching of counting gummies, it is very suitable for various and small-batch production gummy candy counting the packaging.

- Intelligence: The counting machine can store formulas for different materials; recall and use one specific formula at any time after saving.

- The detection photosensor is independent of the gummy channel to reduce the impact of dust on the photosensor; therefore, it ensures high precision and high speed of counting.

- The gummy packaging machine has three-stage vibratory feeding, and each stage is adjustable to ensure a faster flow of gummy candy.

- The feeding mode supports manual feeding and automatic feeding mode.