Softgel Encapsulation Machine Manufacturer and Supplier

Softgel Manufacturing Machine&Service Provider|20+Years Expertise

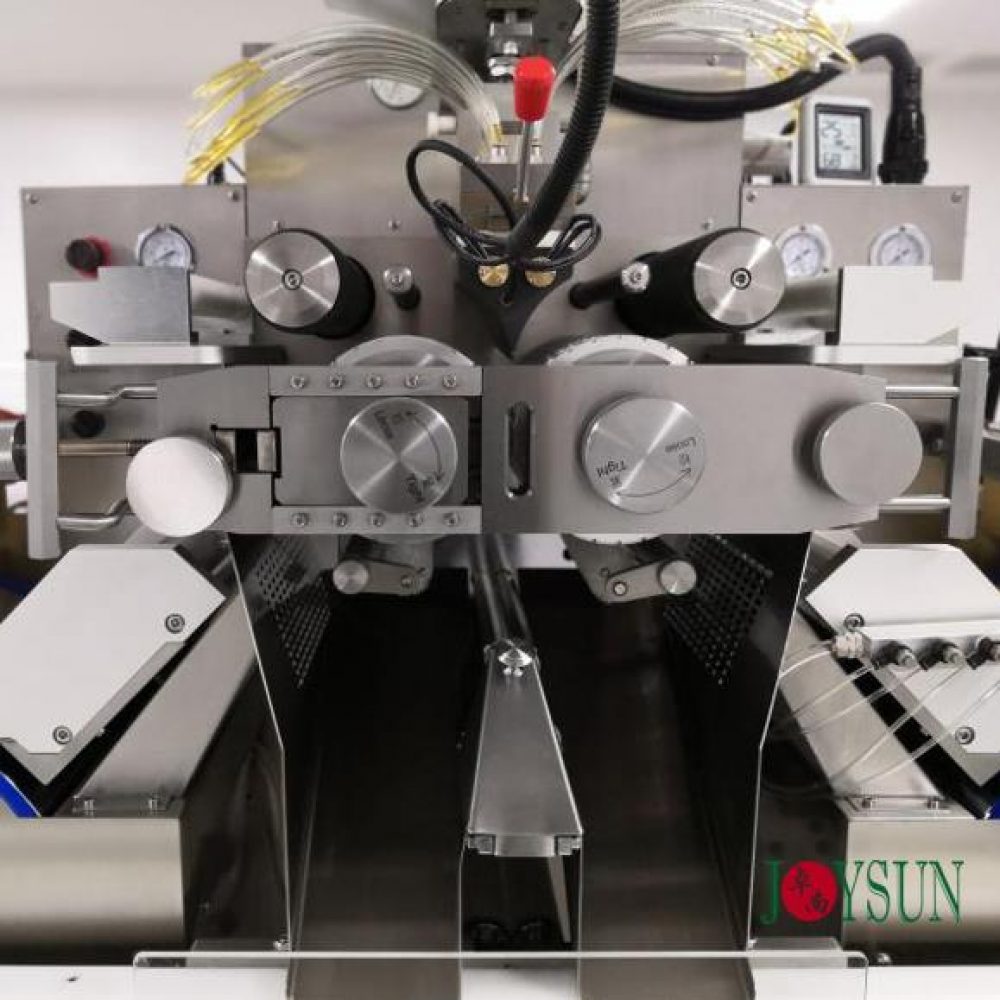

JOYSUN focuses on development and manufacturing of food and pharmaceutical equipment’s, especially on softgel capsule equipment. Major engineer has been in softgel encapsulation machine field for more than 20 years, is familiar with GMP regulation throughout the whole process of machine design and softgel manufacturing. We also have rich experience on paintball manufacturing machinery and paintball formulation.

Our machines ranges from various models of softgel encapsulating machine, from Lab and R&D small scale machine, to medium and large-scale production machine. Different models of softgel tumbler dryer are available, from tiny lab size to Jumbo two-layer design, and can even be customized. We provide top quality softgel tooling (die roll, mold) for not only our main machine, but also for most other softgel machines in the world.

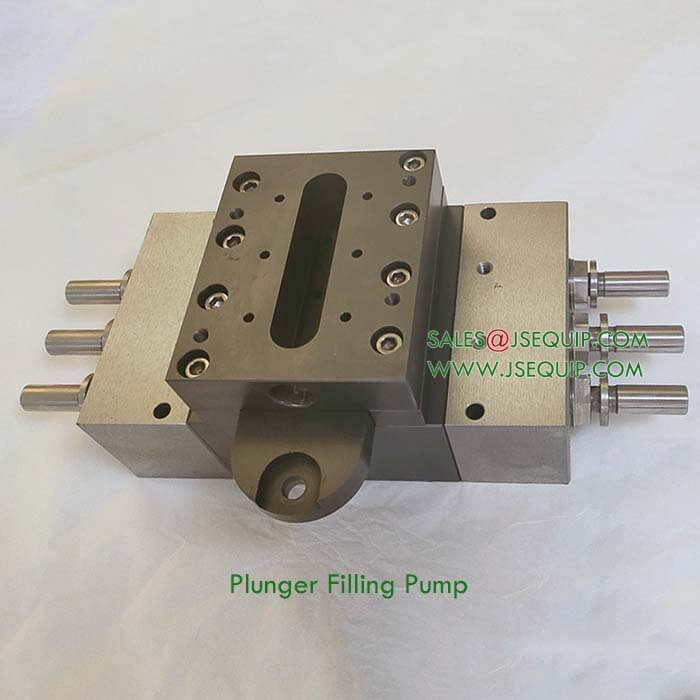

Besides, softgel manufacturing auxiliary equipment also include:

Gelatin reactor (also known as gelatin melting tank, gelatin cooking tank, gelatin mixing tank); Medicament mixing tank (fill mixing tank);

Gelatin receiver (also called gelatin service tank, gelatin holding tank); Vacuum pump system for gelatin melting;

Heat exchanger for gel melting; Platforms for the tanks; Automatic vacuuming system; Softgel cooling conveyor;

Softgel capsule drying trays; Tumble basket automatic cleaning machine; Automatic supersonic die roll cleaning machine;

Capsule size sorting machine; Die roll inspection device; Seamless softgel encapsulation machine

We are strong in vegetable softgel shell solutions. We can provide A-Z solution for veggie softgel capsule production. We are familiar with paintball manufacturing and are able to provide complete solution. We provide not only machinery, but also solutions, technique support; English speaking engineer understands customers’ need, provides best presales service in China. Training and technical support are also our advantages over competitors.

We offer complete line related to softgel manufacturing equipment, including softgel encapsulation machine, tumbler dryer, gelatin melting tank, service tanks, medicine tanks, drying trays, inspection table and etc.

We can design a new project upon detailed user’s requirement URS, upon the room blueprint. Based on our years of softgel encapsulation machines manufacturing and commissioning experience on different projects, we are able to provide buyers with suitable solutions. Except the feasibility of a plant project, we are able to perfect the workflow, so as to reducing labor strength, cutting down energy consumption. Add more automation operation and control.

We are happy to provide opinions, suggestions and advice to clients even you are not using our gummy candy depositors. As long as users are willing to share us with their production issues/problems. We’d glad to discuss with them to solve it. With years in softgel production and good relationship with softgel manufacturers, we are able to provide valuable information. Feel free to contact for such help.

Besides supplying production line and whole projects, buyer can get independent seamless softgel machines from us. We can sell only softgel machine, tumbler dryer, die rolls, tanks and trays to replace user’s current ones. Or to enlarge buyer’s present production need. Machine renovation, fix and auxiliary equipment support is available with us.

Quick Pricing and Quotation

Products

Video Center Product Show

Compare With European Machines, Ours Have Below Advantages.

Short Lead Time

Cost Saving

Spare parts in stock and cost effective

Quick Response

Customer Acknowledgment.

Renovation and improvement.