Description

Softgel and Capsule Inspection Machine Brief Introduction

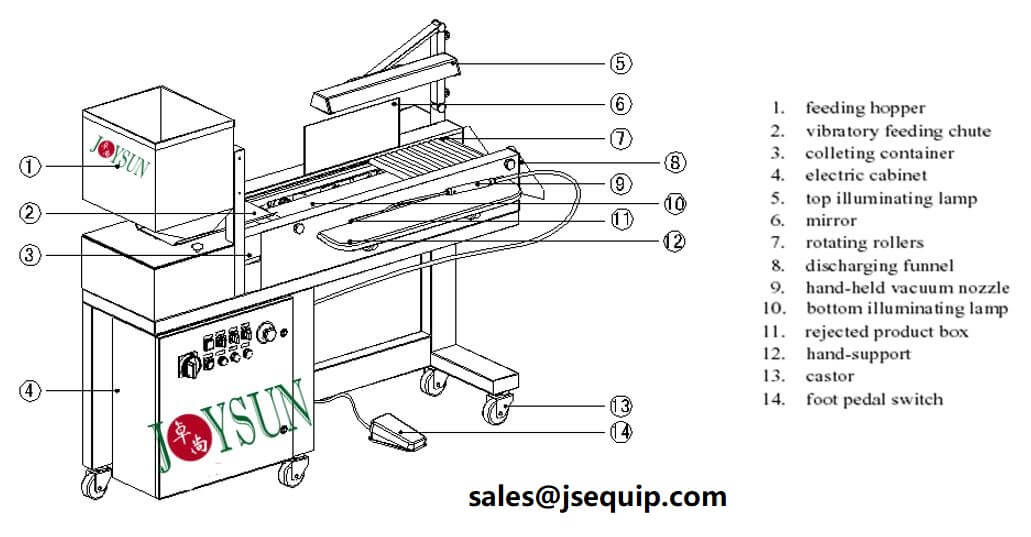

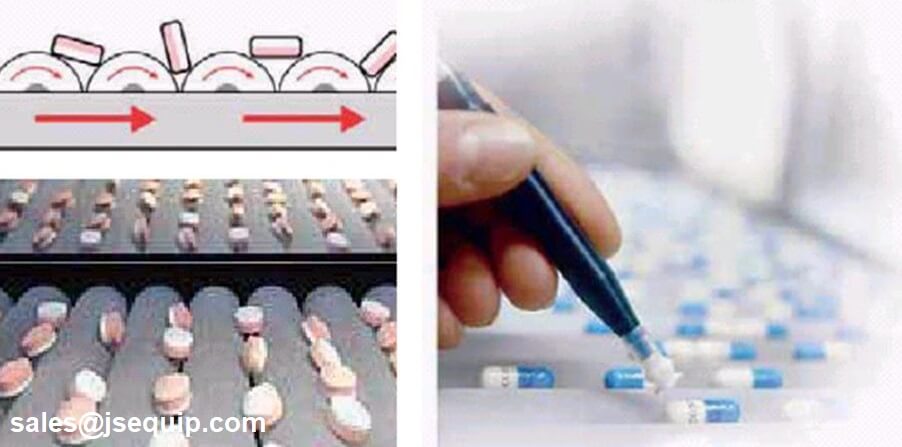

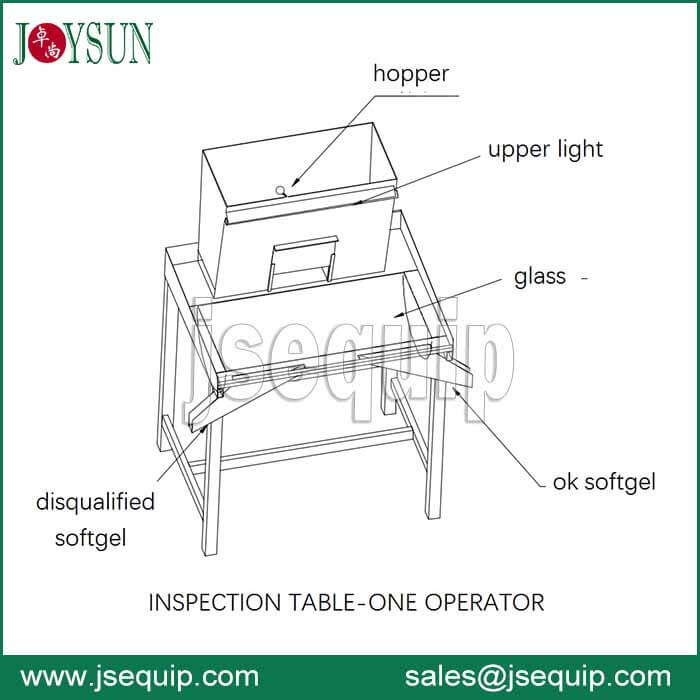

JS softgel inspection machine is for consistent inspection of capsules and softgel and other round and cylindrical objects. The softgel capsules flow from the feeding hopper into a vibratory chute where a perforated screen eliminates coarse dust and chips which are then collected in a container. The product enters the inspection stage in a single layer. The capsules and tablets are placed on rotating rollers and are continuously turned in front of the operator which ensures a reliable all-sided inspection. An adjustable mirror enables the operator to examine the far side of the softgel capsule. Optionally the rotation speed of the inspection rollers is adjustable with a separate drive unit, independent of the inspection speed.

Softgel and Capsule Inspection Table Features

- The rotation speed and inspection speed of the roller are variably adjustable.

- There are no hidden corners and blind areas in the inspection stage.

- Inspection rollers are made of GMP-approved transparent high-density polymers.

- Empty capsules, halves, and chips can be separated automatically with a vacuum unit installed on the inspection belt prior to the inspection stage.

- Defective capsules softgel and tablets can be eliminated by the operator with a flexible handheld vacuum nozzle.

- Foot pedal switch to stop the conveyor belt at any time. While the foot pedal is pressed, the product keeps rotating on the rotating roller at a separately adjustable speed.

- The lighting source from the top and underneath for illuminating the inspection stage is a non-flashed fluorescent lamp. Fatigue of the vision can be reduced.

- For cleaning purposes, the machine can be completely dismantled without any tools within a few minutes. Easy to clean, no cross-contamination risk.