Description

Softgel Tooling

Softgel Machine Spare Parts| Softgel Tooling

Joysun keep a steady stock for softgel tooling and spare parts that may need frequently. So that our clients can replace their wear-out softgel machine parts ASAP to avoid delaying production.

The softgel tooling we kept.

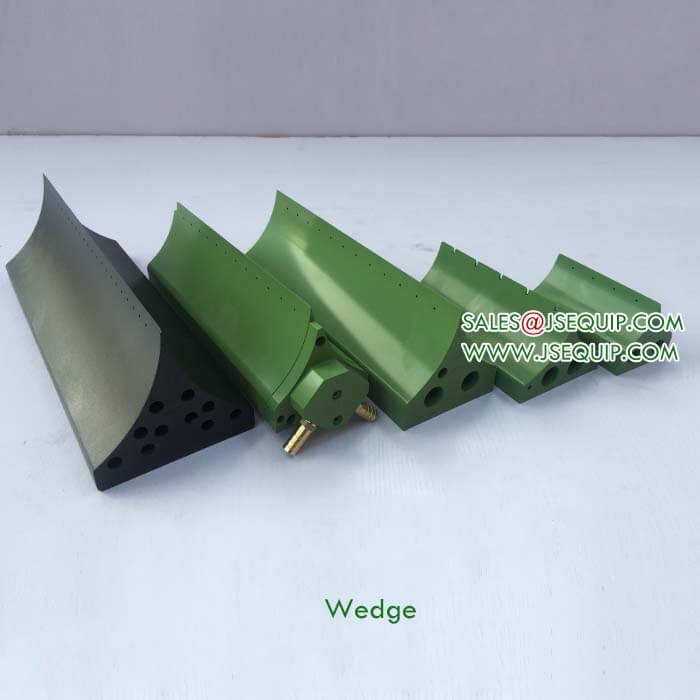

Softgel Dies, Wedge, Distribution plate.

We can make or customize distribution plate and injection wedge with or without die rollers, separately without the softgel die roller. Buyer can choose to send us their old spare parts to measure or just provide a few data for us design. A matching and accuracy set of spare parts are ensured.

Our biggest size Softgel Injection wedge currently is 320*120mm for servo types softgel machines. Joysun provides various types of injection wedge such as vegetable tapioca starch softgel wedge, wedge for oil, suspension, paste, cosmetics softgel wedge. Upon heating difference there can be water circulation wedge and electric heating wedge to keep a constant temperature. Injection wedge repair, recoating is also available.

Gelatin Spreader Box and Spreader Box Spring

The two gelatin spread box is fixed on both sides of the encapsulation machine and suspend above the gelatin ribbon drum. The gelatin liquid is spread on the rotating gelatin ribbon cooling drum to form gelatin film. The heating pipe and temperature sensor are set on the gelatin hopper. Read and set the temperature degree of the gelatin box from the touch screen. The gelatin solution temperature in the gelatin box also can be controlled to reach the set temperature by the touch screen. We can adjust gelatin ribbon’s thickness and uniformity via screws on both sides of the gelatin box. There are temperature control and liquid level control for the gel box.

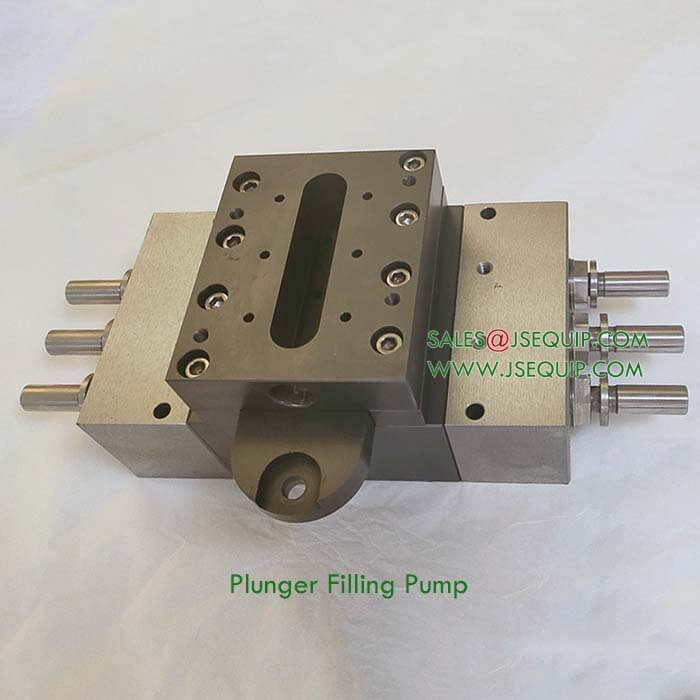

Medicine Filling Pump| Injection Pump| Injection Plunger

The injection pump (also called feeding pump) is a critical part of the softgel encapsulation machine which can precisely inject liquid into the inner softgel capsule. There can be injection plunges in 20sets, 16sets, 8sets upon machine production speed. Joysun mainly has 3 sizes of filling plunges for small, medium, and large size softgel capsules so as to ensure the filling accuracy. Two adjustable handwheels control the filling quantity, thus to change softgel sizes. Our filling pump tries to reduce friction as possible as it can to increase the smooth running of die roll. A less friction can increase service life of filling pump and less leakage of softgel. There are PTFE Seals on the injection plunges. We have two types for option such as O ring type and V shape type.

Lubrication Filter| Lubrication Roller

The lubrication filter right beneath gelatin ribbon is made of UHMW-PE, ultra-high molecular weight polyethylene. It is one of the frequently replaced parts. We can do OEM for such order. Tell us the size and quantity, we can offer.

Sanitary Hoses and Tubes

The usage of softgel encapsulation machine requires several kinds of silica tubes and hoses to transfer gelatin solution and medicine liquid. We can offer small size 12mm, 8mm and etc. silica hose for peristaltic pump transfer. And also bigger size φ38, φ22 for conveying onto tanks. The hoses can be classified into atmospheric ones which bears positive pressure or incases with stainless steel wire inside to hold vacuum pressure. The hose connection can be TC tri-clamp quick connection or left as it is for the user’s to piping.

Other small spare parts like brush on the stripper, compress air connector, gelatin solution filter bag, filtering cloth, softgel conveyor of PTFE material, softgel conveyor of stainless steel mesh net material, gelatin ribbon stripper and etc.

We not only have spare parts for our own softgel encapsulation machines, also can make customized sizes for other softgel machine brands in market. Welcome to inquiry, customization is available for different brands of softgel encapsulators.