Description

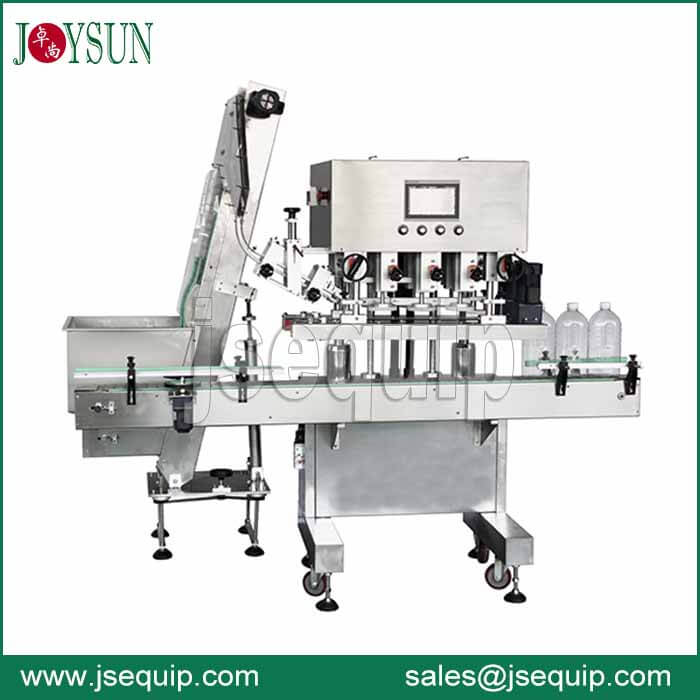

Bottle Screw Capping Machine

GX series bottle screw capping machine is an automatic machine specially designed for the pharmaceutical and food industries. The equipment is composed of cap lifting, cap arranging, capping, conveying, and rejecting mechanisms. The bottle is automatically capped after entering the working station. The bottle is clamped by the bottle clamp and then sent to the capping mechanism to tighten the bottle cap. After the cap is tightened, this equipment will detect the inclined cap and crooked cap, and reject the unqualified bottle to ensure a high capping success rate.

Bottle Screw Capping Machine Characteristics

- The whole machine adopts PLC control, touch screen with Chinese and English interface, and the operation display is clear and easy to understand;

- The bottle-clamping belt is adjustable individually to make it suitable for bottles of different heights and shapes;

- Equipped with a lifting motor, which can realize the automatic lifting and lowering of the working table;

- The parts in contact with the bottle and cap use sanitary material;

- The adjusting screw is having a digital display, which reduces the difficulty of operation and adjustment;

- Automatic cap arranging and capping, reducing labor intensity

- The body shell is made of stainless steel 304 material, which meets GMP;

Optional

- magnetic powder torque limiter

- bottle cap guide device

- defective products and no aluminum foil detection

- data storage and read management