Description

What is Dripping Pill?

Dripping pill is a kind of solid medicine form of a round shape whose preparation includes solid powder/liquid material and matrix base. It is a fast effective medicine. This formulation is widely applied in Chinese herbal medicine(TCM). So in many cases, dripping pill refers to herbal dripping pill. Currently, the popular medicines known to be made into herbal pill are antrodia cinnamomea dripping pill, salvia extract(Dan Shen) pill.

The main ingredients are effective medicine ingredients and mixing bases. During dripping pill making, we also need coolant.

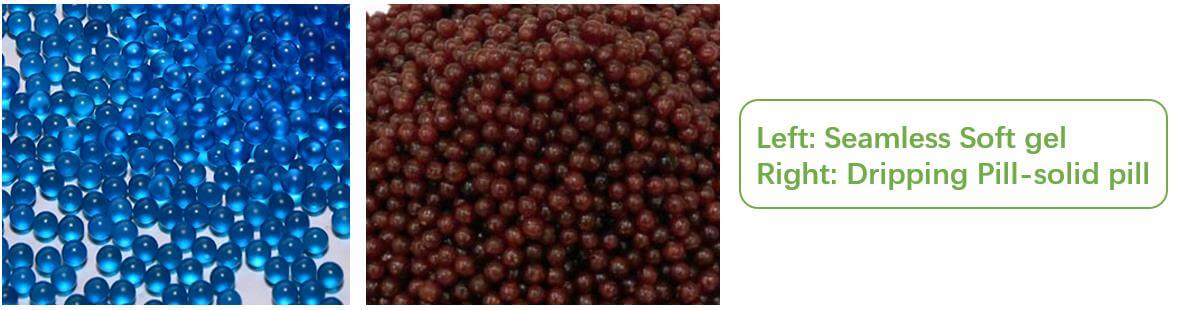

Many people mix up the seamless softgel capsule with dripping pills because they both appear to be small round shapes. And the encapsulation machines to make them look very similar to each other too.

One major distinction is that seamless softgel has a layer of gelatin shell wrapping the inside filling material, the inside content is liquid status. While the dripping pill is a solid herbal pill, no shell wrapping as an extra layer. The dripping pill is a round solid pellet; when using hand to press the pill becomes a solid paste.

There are several requirements to be qualified as a mixing base.

1. non-toxic, no side effects.

2. non-reaction to main ingredients or non-effect medicine effectiveness.

3. low melting point, under temperature 60-100℃, should be liquid status; becomes solid under the impact of coolant.

There are mainly two types of coolants.

1. Hydrophilicity: hydrophilic solution, alcohol solution of different concentration, dilute acid solution.

2. Lipophilicity: Dimethicone, white oil, Methyl silicone oil, and vegetable oil.

Herbal Pill Making Machine Demo Video

How to Make Herbal Pill? Checking the dripping process video.

Herbal Pill Making Process Characteristics

♣ The equipment to make dripping pill is not complicated; the process procedure is simple; short production cycle, low labor intensity. Production cost is much less than tablet production.

♣ Main ingredients are dispersed evenly among mixing bases, so the difference in drug dissolving, content and weight are little.

♣ Low loss rate: Due to the short preparation time, small temperature range, the medicine will be more stable.

♣ The medicine and matrix do not need to be crushed or ground, and the production area is free of dust, which is conducive to labor protection.

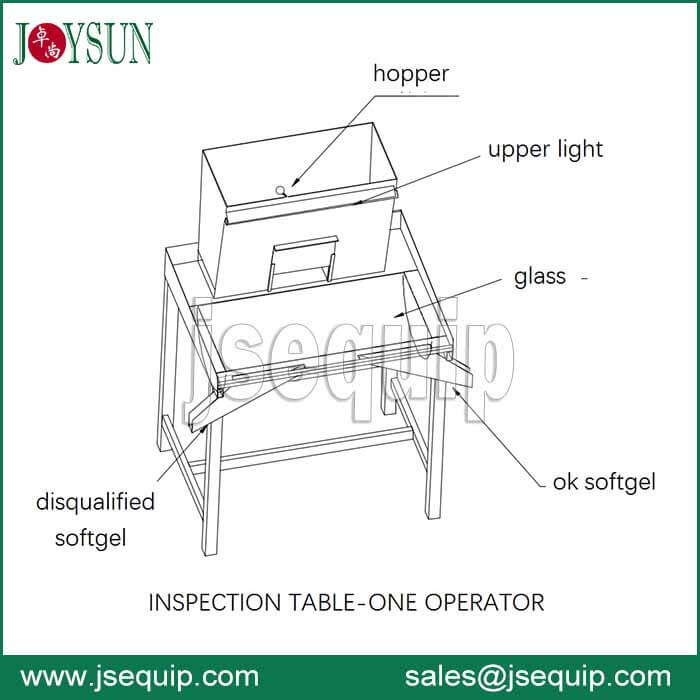

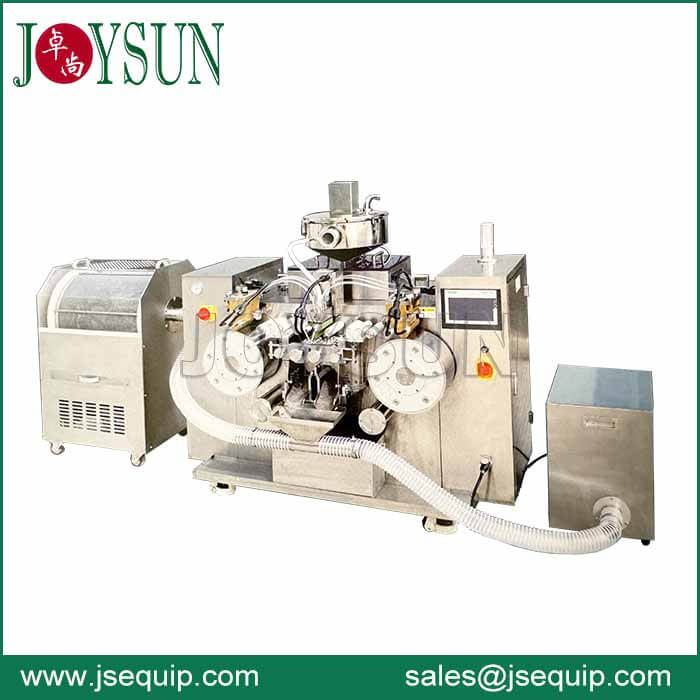

Production Equipment to Make Dripping Pill

Raw Material Mixing Tank 20-60Liter

Mixing tank consists of three layers, inner barrel, heating layer, insulation layer, and cladding; With the stirring system, heating and temperature control system used to prepare the main ingredients for herbal pills.

Pellet Centrifugal Device

It is composed of pellet collection and oil centrifugal function which functions to collect dripping pills from coolant and then get rid of extra coolant on the surface of pellets. The small medicine balls under the impact of centrifugal, spinning quickly inside the barrel and fastly dried.

220V/single phase/0.6kw; 0-2600rpm rotation speed with variable frequency control. The micro balls centrifuge can be time setting automatically. Approximate size: 1000*500*1000mm; gross weight: 100kg.