Description

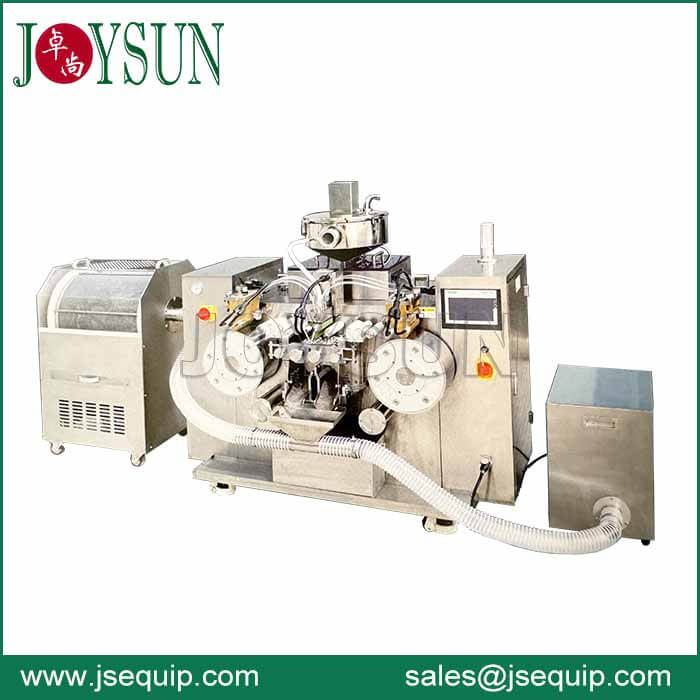

Lab Small Softgel Manufacturing Equipment

Joysun Pharma Lab Size soft gel capsule machine is designed for R&D purpose innovation of making new types of soft gel capsules(Size, Shape, Manufacturing Process Guide). It allows for making new animal softgel or vegetable soft gel with minimum material waste and less cost. Joysun softgel machine is your best choice for trial production as a starter.

A lab softgel encapsulation machine requires much fewer raw materials, for example, a 20L gelatin solution can be used for 4-5hours. While the big machine needs at least 20L gelatin to initiate the encapsulation process. It requires a much lower production cost. Small size soft gel machine is easier and fast to be cleaned in a short time. Also, speed up softgel variety change.

Lab Softgel Machine Encapsulating Video

Small Size Soft Gelatin Manufacturing Equipment Characteristics

Adopts the newest tech and material, and reaches GMP requirements. Using a single-phase, 220V power, mainly applied for lab and pharmacy institution R&D experiment and small-batch produce. This machine adopts an automatic control system, and has characteristics such as easy operation, and stable and reliable performance. The whole soft gel capsule manufacturing machine was well-designed, has necessary functions, and has a compact structure. A whole set includes the main machine, a control system, a tumbler dryer, a vacuum mixing tank, a set of die rolls, a removable platform, and an air blower.

A. The encapsulation part is the main machine, which can complete functions like gel ribbon making, capsule content measuring, and soft gel sealing. The vacuum mixing tank is for gelatin melting, storage, and supplying gelatin solution to the encapsulation machine. Tumbler dryer is for soft gel shaping and drying.

B. Tumbler dryer consists of a tumbler, fan, and motor. It can keep soft gel capsules in the tumbler or discharge by reverse rotating. It is mainly used for capsule shaping and drying.

C. Movable platform: Main machine, drying machine, and electric control box were mounted on this platform, for moving easily.

D. Control system: Realize the whole device’s normal and automatic function.

E. Water chiller: For gel ribbon cooling.

Industrial high-speed mass production softgel encapsulation machines.