Description

High Capacity Softgel Pulverizer

Softgel Pulverizer Description

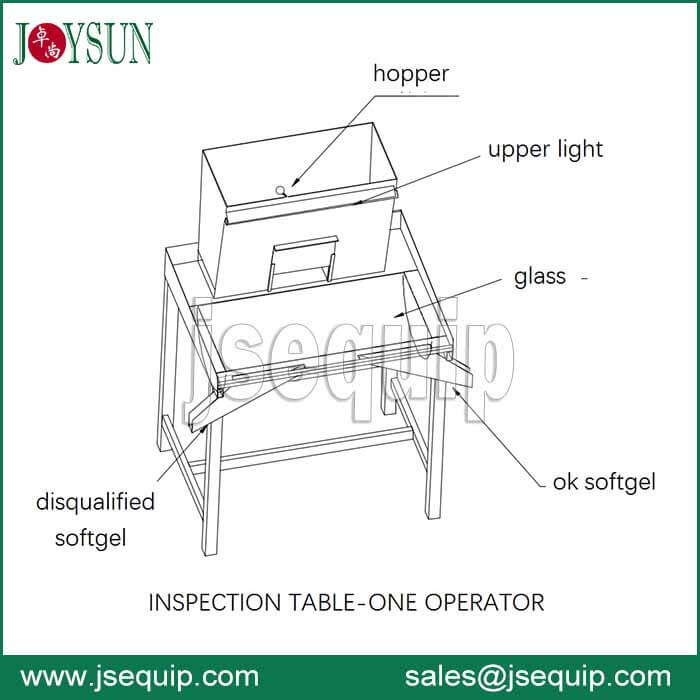

Joysun softgel pulverizer is to ‘recycle’ misshaped or unqualified softgel capsules. The machine works to separate softgel into shell and inside medicine solution. To get the inside filling material back and re-use, saving a lot of cost during softgel manufacturing. It is easy to clean, easy operation, easy maintenance, and with a simple compact structure. A desirable and efficient machine to recycle softgel capsules. Main Components: Hopper, centrifuge barrel, softgel hopper, cutter, frame, motor, and a control box. The reasons why you should choose it is that especially for beginner to producing softgel, they can easily go wrong and make deformed softgel or not strongly-seam softgel.

Other auxiliary equipment for softgel manufacturing:Operation

Load softgel into the hopper on the top.

Turn ‘ON’ the machine, it starts to break the capsules. The filling liquid falls out from the centrifugal during working. The gelatin shell stays inside the hopper till the user takes them out. This way increases the material recycling rate.

Turn ‘OFF’ to stop the machine.

Disassemble the softgel grinder to clean if the user changes to another batch of production. The disassemble is easy, only takes a few minutes.