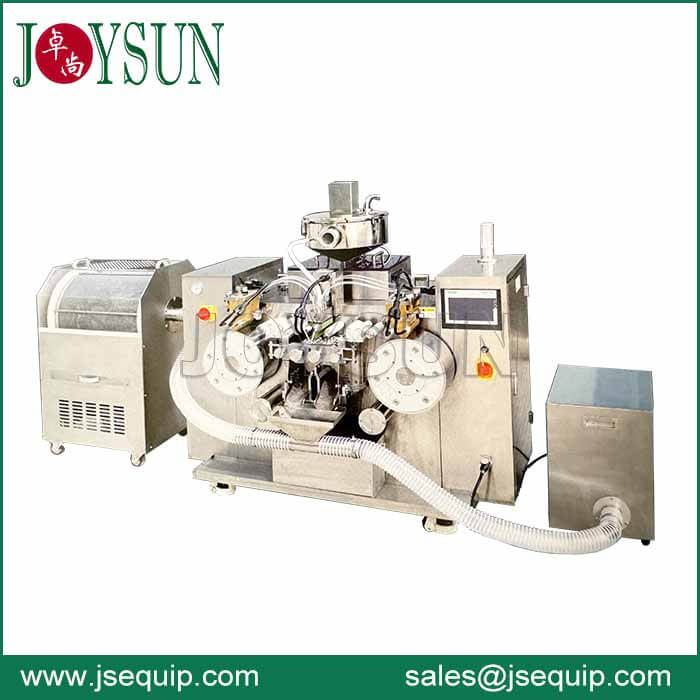

Description

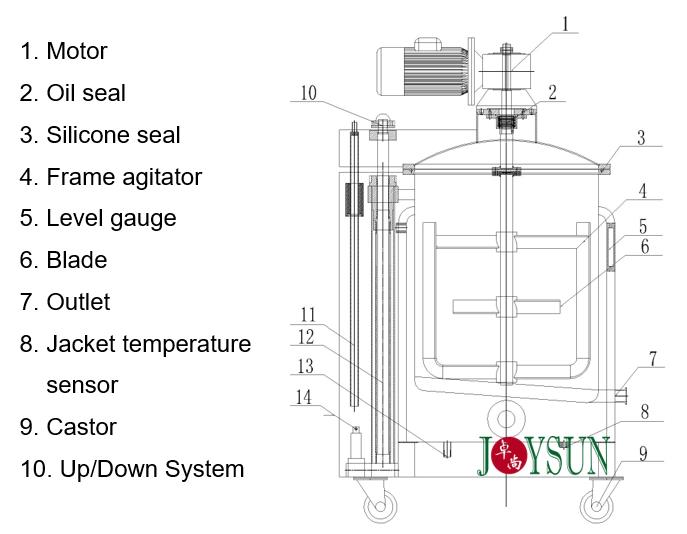

Small Soft Gelatin Melter 50-100L

50-100L small soft gelatin melter is ideal equipment for trial and pilot softgel manufacturing. Customized for lab usage, suitable for the institution, university, and other small factories usage.

Features

- Though it is small and compact design, with all functions that big gelatin melter has. So when enlarge production, can refer to the same working condition.

- Good airtightness and high vacuum withhold;

- Hot water jacketed and heat preservation cladding;

- Suitable for animal gelatin as well as vegetable material such as carrageenan powder, starch powder and compound powder.

- Tank lid can lift and lower.

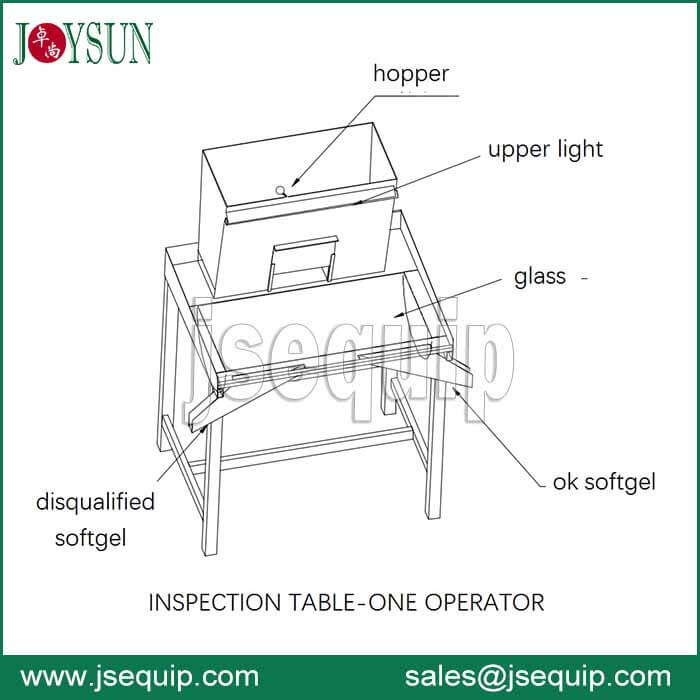

- One worker is ok to use this tank.

- Can movable around with strong castors.

Tank Options

- Built-in vacuum system or outer vacuum station

- Electrical lid up/down or pneumatic type

- Hot water jacket or hot oil jacket

- Different types of stirrer and agitator to choose

- VFD controlling or fixed speed

- Lower port discharge or high level port discharge

1.Motor: Installed at top of the tank to drive gelatin melting agitator; we adopt a horizontal motor instead of a vertical one, to reduce the overall height of the tank after gelatin tank lid lifting.

2.Lip seal: Strong NSK oil seal is used so as no oil leaked from the motor and reducer.

3.Silicone seal: The overall airtightness for the gelatin tank inside using sanitary degree silica sealing at the tank flange. To ensure good sealing and high vacuum degree during melting gelatin.

4.Frame agitator: agitator steadily and slowly rotate inside gelatin solution to help material dispensing and melting.

5.Liquid level view: this is to check heating media inside the jacket to avoid jacket dry burning. If water or oil content is lower than this level, it should be re-filled in time.

7.Outlet: material discharge port is at tank bottom side; though it is not at the center bottom, there is a slope to ensure easy and full material unloading.

8.Jacket temperature sensor: to detect the temperature inside the jacket; by this to control the heating temperature of raw material.

9.Castor: gelatin melting tank can be moved around and put away.

10.Up/Down System: The tank lid with motor and reducer is over 50kg; it is not an easy job to open or close the lid by one worker, so this design can open the lid by stepping on the foot pedal. Effective and Practical.

Checking out the big gelatin melting tank.