Why Does Softgel Leak? Possible Causes for Softgel Leakage

- by Sharry

- July 5, 2022

Why does softgel leak? Possible Causes for Softgel Leakage

Brief Analysis of Abnormalities Such as Softgel Leakage and Bad Seam on Softgel Capsules.

The softgel leakage can happen due to many reasons and causes. Those causes influences among themselves, becoming quite complicated. So for a beginner, it is hard to find the reason. Keeping the die roll in good shape and non-damage is one of the most important things to do. The basic installation and operation of the die roll is the most basic and yet most crucial thing in using the softgel encapsulation machines. Other basic controls such as room temperature, humidity, machine heating temperature, and cooling temperature are not discussed here.

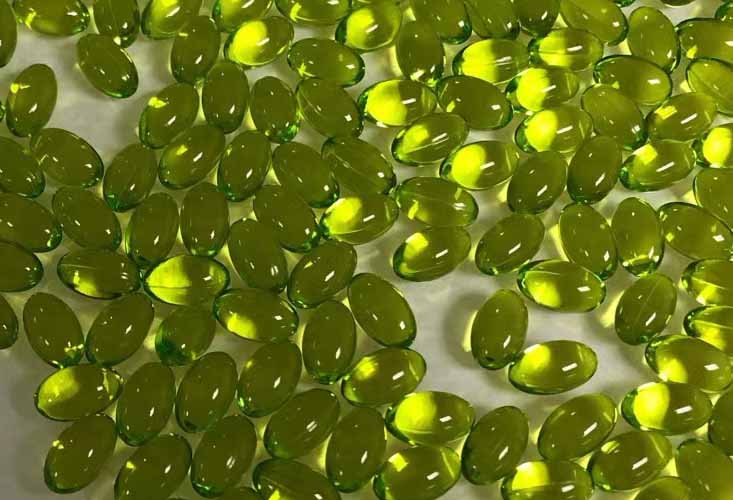

- The most likely cause of softgel oil leakage is the low viscosity of the gelatin mass. When the softgel encapsulation machine runs relatively fast, the moisture of the gelatin solution is high, hard to evaporate by the cooling drum and fan. So after encapsulation, the softgel enter drying process, leak gradually. Low viscosity also results in poor adhesive ability, such as a poor seam. Pay attention to the gelatin powder quality using, at least should be ≥150lb; the proportion among water, gelatin powder, and glycerin; the final water content in gelatin mass after melting. However, a too viscous gelatin solution might also fail to form a good sealing, which ends up leaking too. One reason is that die roll is difficult to cut gelatin ribbon off. Therefore, the operator should have a standard checking for the gelatin solution. The gelatin melting process should be well and strictly controlled and carried out. An SOP(Standard Operating Procedure) for gelatin melting is strongly suggested.

- The abrasion or damage of the wedge will cause a non-symmetric softgel shape, such as softgel bending, one side big and one side small, the seam non-straight. Thus there is a risk of softgel oil leakage. The heating rod on the wedge is very important too. When the two heating rods heat up unevenly (such as one is particularly hot), or the temperature controller of the wedge fluctuates greatly; the shape of softgel won’t be good. Under these circumstances, the leakage may not be found instantly. But during the softgel storage, there might be leakage.

- Synchronization matters greatly. Whether the injection pump, wedge and mold cavity are synchronized, if a little bit deviates, will also cause leakage.

- Keep injection holes clean. If the injection hole on the wedge is partially blocked, the oil filling will not be accurate. Especially in the production of soybean lecithin, Chinese herbal softgel capsules, there will be softgel leakage.

- The left and right sides of the dies must be clean, and the vent holes in the cavity should be clean too, non-blocked. Otherwise, the softgel filling material sticks inside the cavity, and softgels are hard to fall off. At the same time, it will also affect the softgel deformation, reduce the filling volume, and softgel leakage.

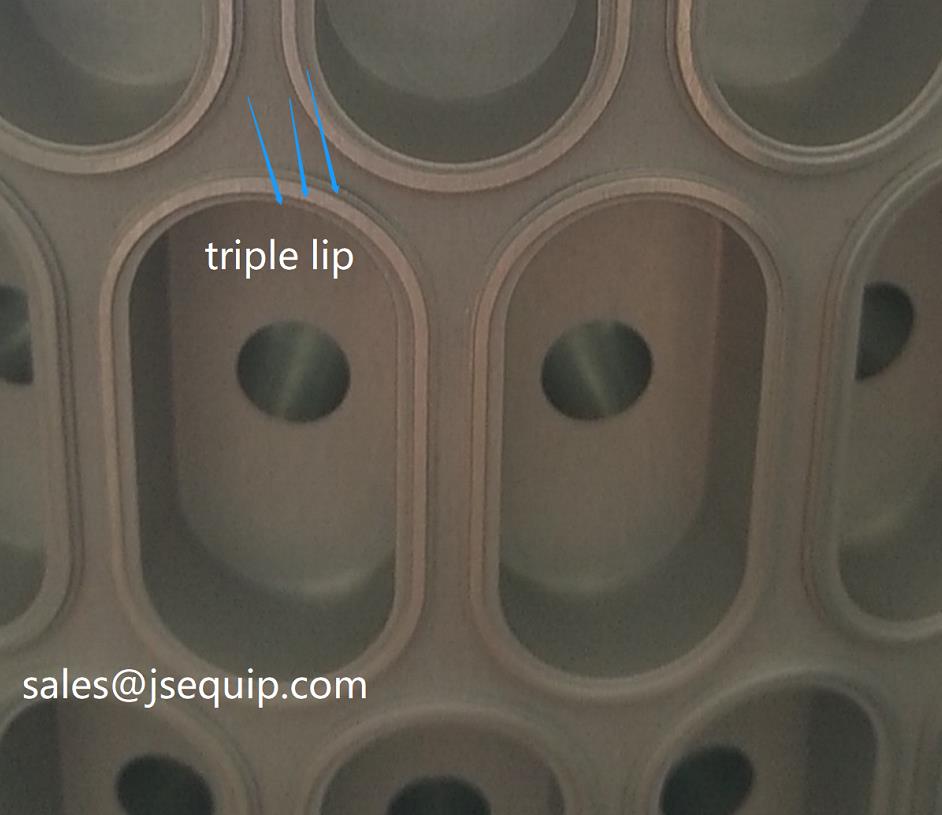

- The softgel die lip is worn out, cannot cut gelatin ribbon properly. Cutting not good, softgel falling off only relies on the gelatin ribbon stripping process, there might be softgel leakage or a rough seam. Thus good cutting of die roll is crucial. During the softgel die design, select single lip, bi-lip, or triple-lip dies properly upon your actual material.

The design of die cavities is too small to hold overfilling oil. For example, the die is for 500mg oil, yet the operator tries to fill more such as 600mg, 700mg. This happens quite often in suspension-type softgel. Because machine user doesn’t know how to calculate the best size for filling paste. The cavity size design for oil and for suspension is different.

Some softgel leakage happens during the storage stage, this can relate to the formula of softgel. As in some softgel filling, the medicine contains PEG and water, when the water is up to 5%, the formula process and preparation should be careful such as Ibuprofen softgel.