What to Do When There Is Bubble Or Air Inside Softgel?

- by Sharry

- July 5, 2022

What to Do When There Is Bubble Or Air Inside Softgel Capsule?

For beginners who just start to do softgel manufacturing, they will encounter problems this or that frequently. One of the issues during softgel production is that after softgel dried, there are air/small bubbles inside the softgel capsule. The causes of such a problem can be many. Below Joysun lists some of the common reasons. Softgel Encapsulation Machine operators can take a rough reference from.

Possible Cause 1# Gelatin Solution

The most obvious and easiest cause that ends up having air inside softgel is that there is air inside gelatin solution. This means workers not melt and prepare gelatin solution well. The gelatin deaeration process should be carried out thoroughly. Thus the air is actually existing in the gelatin shell.

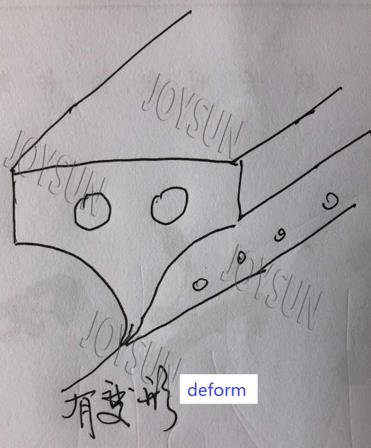

Possible Cause 2# Wedge

After we rule out the raw material preparation reasons. We need to check possible causes from the softgel machines. The deformation of the wedge might result in releasing air into softgel during medicine injection.

2.1. Use your hand to touch the edge of the softgel wedge, to feel very carefully whether there is damage or deformation; if yes, the wedge needs to be replaced.

2.2 The position of the wedge on the softgel machine is important. Check whether the wedge drops down naturally to its right position (should not be hanging in the air). With the updated servo softgel encapsulation machines, the placing of the wedge/die roll is much easier than before.

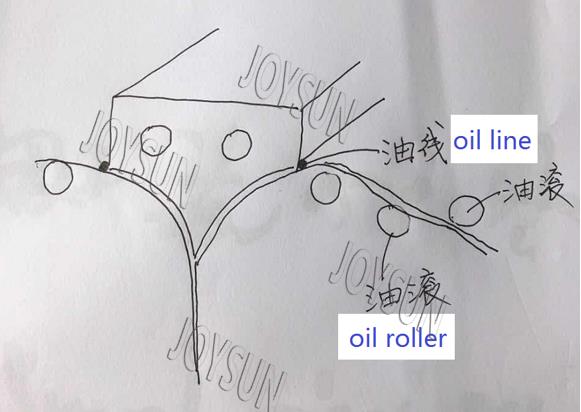

Possible Cause 3# Lubrication

3. Not enough lubricants for the gelatin ribbon will also cause the air inside softgel. There should be a continuous oil line to lubricate the gelatin ribbon. Check as the below shows and improve lubrication. After a period of usage, the operator should replace the lubrication rollers to keep the softgel encapsulation machine work at high efficiency.

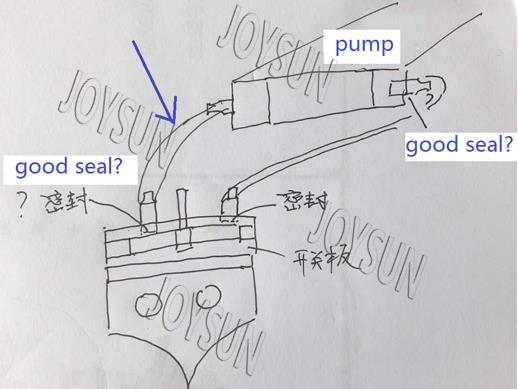

Possible Cause 4# Leakage

4. Checking the oil pipes, transparent pipes as below photos shows, make sure connection is good, otherwise, air will go in the pipe and fill into softgel(please be very patient and careful to check). Inspect those pipes for a period of time to see whether will be small air bubble appear (the bubble will appear slowly, not always exist, so need to inspect with patience). For some factories, this might be the main cause.

Possible Cause 4# Others

5. Filling material itself with air bubbles. Open the medicine hopper on top of the softgel encapsulator, inspect whether the bubble will pop up (inspect for a period of time, the bubble is not always there); If there is, the medicine material needs to retreat.

6. If your product is fish oil softgel. There can be another cause. Take some softgel capsule samples with bubble inside, cooling them as normal softgel to see if bubbles will disappear after dried and cool down. If yes, then ignore this bubble problem during encapsulation. Because such is caused by the temperature difference of fish oil temperature and wedge working temperature. The bubble will disappear finally.

Joysun tries its best to make softgel encapsulation machine more stable and reliable to use. We also try to give suitable suggestions to help user troubleshooting during softgel manufacturing. Welcome to contact us, hope we can improve together with our clients.