Softgel Gelatin Ribbon Regular Troubleshooting

- by Sharry

- June 13, 2022

Regular Troubleshooting for Gelatin Ribbon

The user will come with encapsulation problems and softgel quality issues during the softgel manufacturing process. Below will focus on the issues and problems related to gelatin ribbon. What influences the gelatin ribbon and what happens if it is not prepared well. Check the basic checking points as follows.

1# Issue: there are breaks or grooves on the gelatin ribbon.

The main reason for this might be a foreign object at the outlet of the gelatin box. The user should remove this foreign object. Or the gelatin solution cools down to become a solid mass, then remove that mass. Keep the gelatin box clean is important.

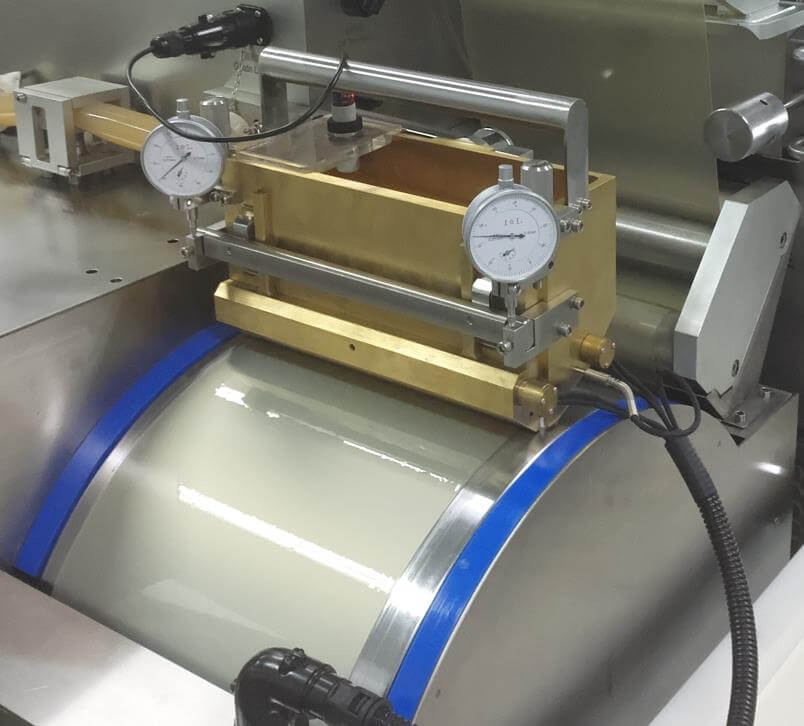

2# Issue: The thickness of the gelatin ribbon is not even or with a waved surface.

The possible reason could be that there is not enough lubricant on the cooling drum. Or there are foreign objects on the gelatin ribbon drums. Suggest the user to lubricates the cooling drum or clean up the gelatin ribbon drum. The drum solution should keep clean and smooth.

3# Issue: The gelatin ribbon is piled between the oil roller and die roll.

A major guess for this phenomenon is that the die roll wedge is not placed properly, Or the mangle rollers are too loose. The operator should adjust the wedge’s position and press the mangle roller tightly.

4# Issue: The width of the gelatin ribbon is shorter than it supposed to be.

There might probably be a foreign object at the outlet of the gelatin box. So when the gelatin width is affected by the obstacle. Please remove foreign objects.

5# Issue: The gelatin ribbon gets stuck onto the gelatin ribbon drum, not peel off easily.

This is a problem caused by the temperature. The temperature of the gelatin ribbon drum is a little bit too high. Please reduce the temperature of the gelatin ribbon drum or the temperature of the gelatin liquid gradually, while inspecting gelatin ribbon status. Good circulation cooling for the drum is crucial.

6# Issue: The softgel capsule shape is dissymmetrical.

The operator should know that the softgel capsule is formed by two pieces of gelatin ribbon. Thus both sides of the gelatin ribbon thickness keep should be the same and even. Please adjust the gelatin ribbon’s thickness.

7# Issue: The softgel shell is concave.

The quality of the gelatin ribbon might not good enough. Adjust the gelatin ribbon’s thickness or replace gelatin liquid. The type of gelatin powder should be ≥180LB. The gelatin melting process should carry out strictly to production needs.

Maintenance of Coolant within Cooling Drum

The gelatin ribbon matters in the softgel manufacturing, therefore the maintenance of coolant circulated within the cooling drum matters too. Below are some tips/routine checking.

Regular observation: check the coolant in the pipeline once a month and to see whether the coolant color changed or not; whether suspended objects and sediments appear or not. Replace the coolant timely when the color changes (because coolant quality not good anymore), or have metamorphic objects with an abnormal smell, suspend objects and sediments appeared. Drain old coolant and refill with a new one.

Regular vent: Suggest exhausting the coolant box every three months because there might be bubble/air inside the coolant to affect the cooling performance.

Regular replacement: In general, replace the coolant once every one year and a half. If the softgel encapsulation machine runs every day and each day for more than 16 hours, the coolant should be changed every nine months or a year. If every day the equipment runs less than 8 hours, the coolant can run for about 2 years.