- Home

- Softgel Machine

- Page 2

Softgel Machine

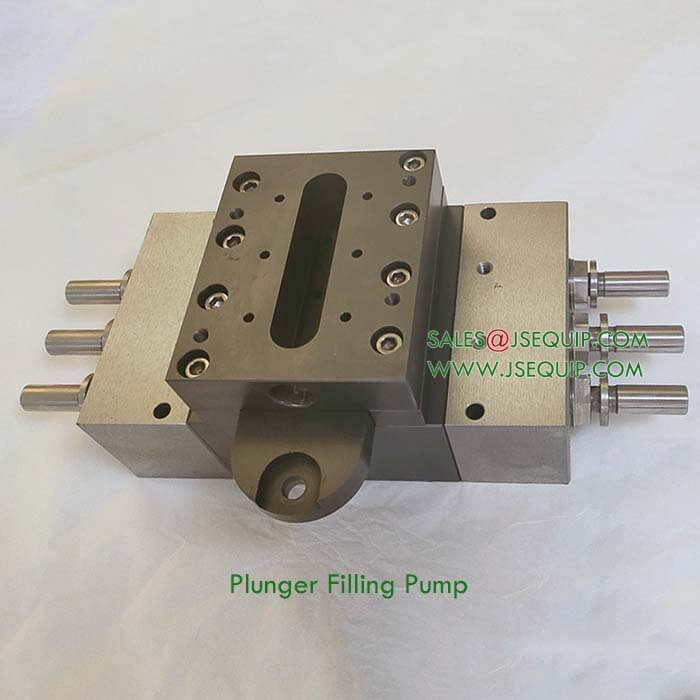

Joysun Softgel Encapsulation Machine manufacturer and supplier provides softgel machines with years of experience and technology. A soft gelatin capsule manufacturing line includes equipment like softgel encapsulating machine, gelatin melting tank, medicine mixing tank, tumbler dryer, drying tray, softgel tooling, capsule inspection table and softgel polisher; as well as a series of auxiliary equipment differ upon softgel manufacturer’s site condition.

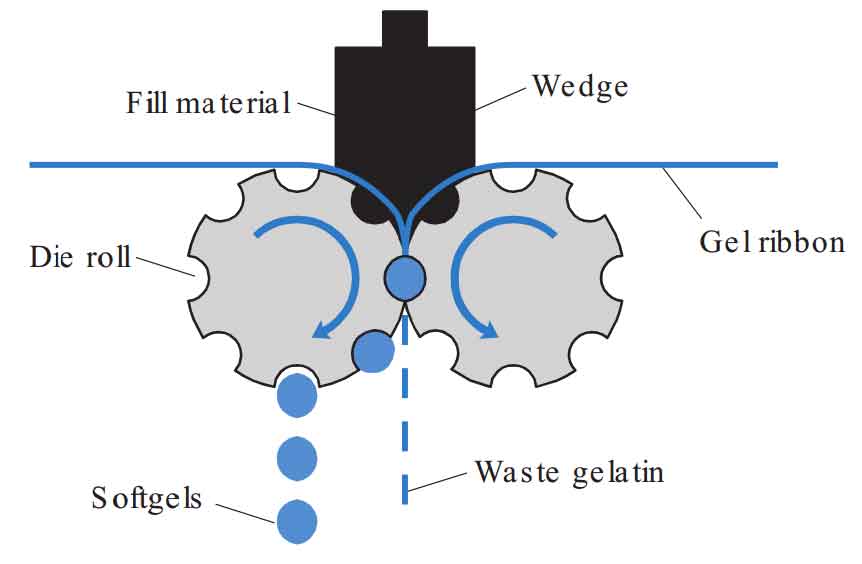

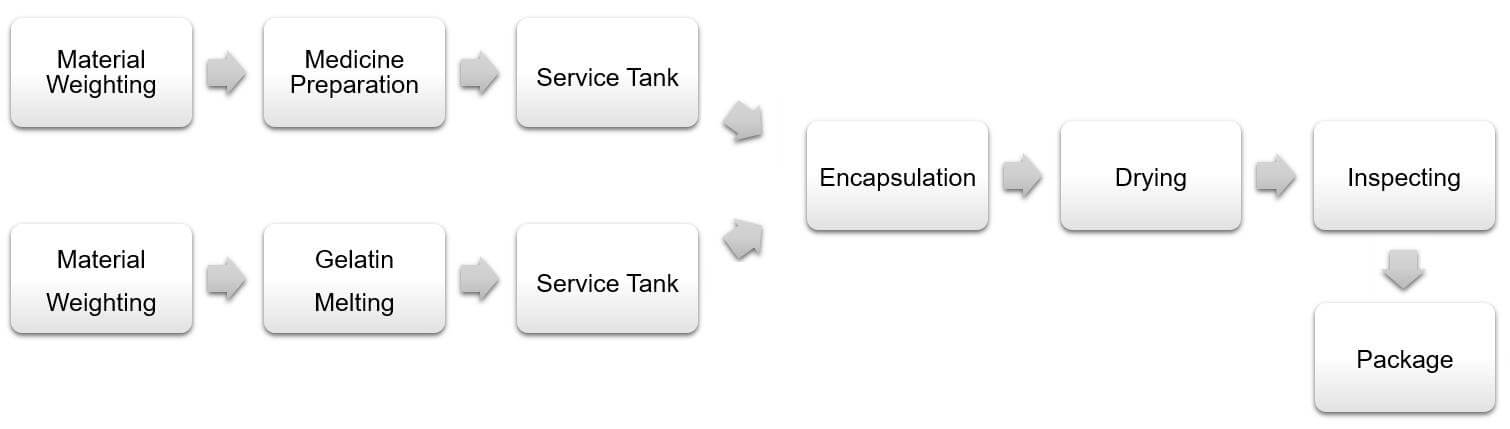

The softgel capsule filling machine encapsulation mechanism is that the gelatin ribbons wind up upon the guidance of die rolls; sets of plungers inject medicine into the pockets formed by gelatin ribbon; while at almost the same time, gelatin ribbon is cut off under cold press. Thus the shaped balls fall down from the dies and become softgel. The ‘soft’ softgel transferred to a tumbler dryer for pre-cooling, drying, going to inspection, and packaging.

Quick Guidance on Softgel Manufacturing and Softgel Machines.

We’d like to introduce briefly about softgel manufacturing and related machinery and devices over below questions.

- What is ‘Softgel’?

- What’s the benefit of ‘Softgel’?

- Softgel Encapsulation Machine Origins Briefly?

- Softgel Workflow in Summary?

- What equipment does Softgel Manufacturing need?

- What Auxiliary devices need in softgel production?

- What is softgel production room temperature and humidity?

- How many personnel need to use softgel encapsulation machine?

What is ‘Softgel’?

It is an oral dosage capsule with a layer of a gelatin-based shell(sometimes veggie raw material shell) filled with oil/medicine inside. The solution should be fat-soluble liquid or a little water-soluble material is allowed upon detailed recipes. This is due to that the hydrophilic material will suck water from the shell and break the softgel shell, which leads to softgel leakage. Softgels are ideal for oils and fat-soluble formulations.

What’s the benefit of ‘Softgel’?

♦ Softgel capsules have some apparent benefits and advantages compared to other types of dosage forms.

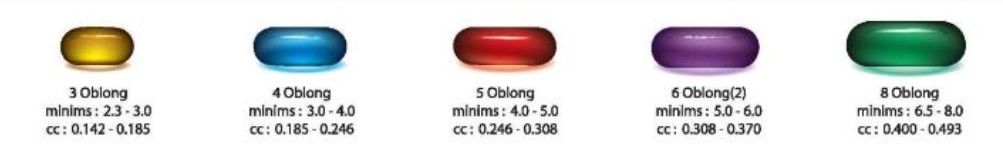

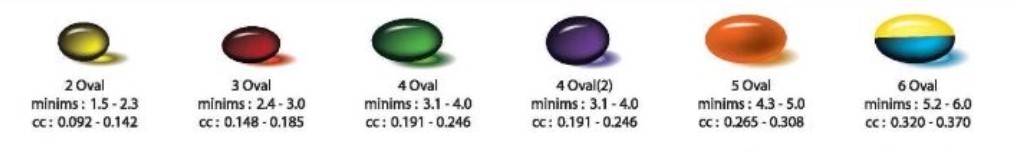

♦ Softgel has a wide range of options in shapes, sizes, and colors, suitable for consumers of all ages. And customized for human beings and animals and pets like cows, horses, cats, and dogs Making softgel easier to swallow.

♦ Softgel capsule is a sealed dosage with a shell outside. The dark color can prevent direct sunlight, airtightness can protect the capsule from oxidation. In this way, the inside medicine is more stable and well preserved, especially for light-sensitive ingredients. And because of the sealed softgel, it performs better under heat and temperature during transportation and storage.

♦ Softgel can fill liquid, suspension solution inside which increases the bioavailability of poorly absorbed or soluble nutrients.

♦ Carrageenan or starch/tapioca type veggie softgel capsule makes it more and more popular among vegetarians or halal people.

Softgel Encapsulation Machine Origins Briefly?

Softgel Encapsulation Machine is also known as a softgel making machine or softgel encapsulator. A specially designed machine to make softgel capsules is available on the market since 1970. Since then several brands of softgel machines emerge with improvement and innovation. Chinese first Softgel encapsulation machine is made in the year 1986. China has over 30 years’ history in softgel encapsulation machine manufacturing, ranging from lab R&D softgel machines to fast speed and servo type jumbo encapsulation machines.

Joysun has engineered over 20years of experience in softgel machine design and die roll design, we are professional supplier to provide users with optimized choices.

♦ Softgel Gelatin Melting

♦ Medicine Filling Material Preparation

♦ Gelatin and Medicine Holding Process

♦ Softgel Encapsulation Process

♦ Softgel Shaping and Cooling Process

♦ Softgel Final Drying

♦ Softgel Packing

What equipment does Softgel Manufacturing need?

| SN | Machine | MODEL | QTY |

| 1 | Softgel Encapsulation Machine | Upon production need | 1set |

| 2 | Tumbler Dryer | To match machine, or upon room space | several |

| 3 | Gelatin Melting Tank | Size and shape can be customized | 1 or 2 |

| 4 | Filling Material Tank | Size and shape can be customized | 1 or 2 |

| 5 | Gelatin/Medicine Service tank | 200L/300L standard | 4 or 6 or 8 |

| 6 | PP trays | Standard | hundreds |

| 7 | Colloid mill | Standard | 1 |

| 8 | Inspection Table | Standard | 1 or 2 |

| 9 | Vacuum system | supplier design | 1 set |

| 10 | Hot water System | customized upon user’s condition | 1set |

| Options | |||

| 1 | Color mixer | ||

| 2 | Softgel Grinder | ||

| 3 | Counting and Packing Machine | ||

What Auxiliary devices need in softgel production?

♦ Purified water: it’s a necessary during raw material preparation and cleanness process.

♦ Hot water source: for gelatin melting.

♦ Vacuum source: Vacuum plays a crucial role in gelatin melting, inevitable to help the de-♦ aeration process.

♦ Compressed air source

♦ Power: 3 phase stable electric power source.

What is softgel production room temperature and humidity?

The softgel encapsulating room: temperature 18-22℃ relative humidity: 35-45%

The softgel drying room: temperature 20-24℃ relative humidity: 20-25%

Other rooms can follow up the cleanroom classification standard.

In most cases, a full softgel manufacturing line should prepare encapsulation room, gelatin melting room, service tank storage room, drying room, inspection and packaging room.

How many personnel need to use softgel encapsulation machine?

A reference only, let’s say 1-2 person for gelatin melting, 1 for encapsulator, 2 for inspection, 2 for packing (generally speaking for continuous production and for 1 line); factories should optimize their personnel arrangement and management.