What Might Cause Softgel Leakage?

- by Sharry

- May 6, 2022

What Might Cause Softgel Leakage?

Softgel is easy to leak due to reasons this and that. It is such a headache for beginners that they have no idea of how to solve it. Here I’d like to introduce several commonly seen situations and provide accordingly solutions. I am not sure it is exactly the cause, but at least provide softgel machine users a general idea of what to look into.

1. The most obvious cause should be the damage to die rolls and wedges.

So keeping the die roll in good shape and non-damage is one of the most crucial things to do. The cutting rim of each die roll cavity should be smooth, no obvious scratch or bump is allowed. The surface of the wedge should be well protected. Feel the edge of the wedge with your hands, and put it under your naked eyes to check the straightness. No curve and breakage of the edge is allowed.

2. The softgel die lip wears out for a period of usage, and cannot cut gelatin ribbon properly.

Then the gelatin stripper has a hard time peeling off the gelatin ribbon from the dies. this might result in bad seaming. During the softgel die design, select single lip, bi-lip, or triple-lip dies properly upon concrete softgel manufacturing needs.

3. Improper installation of the die roll is not rare among users.

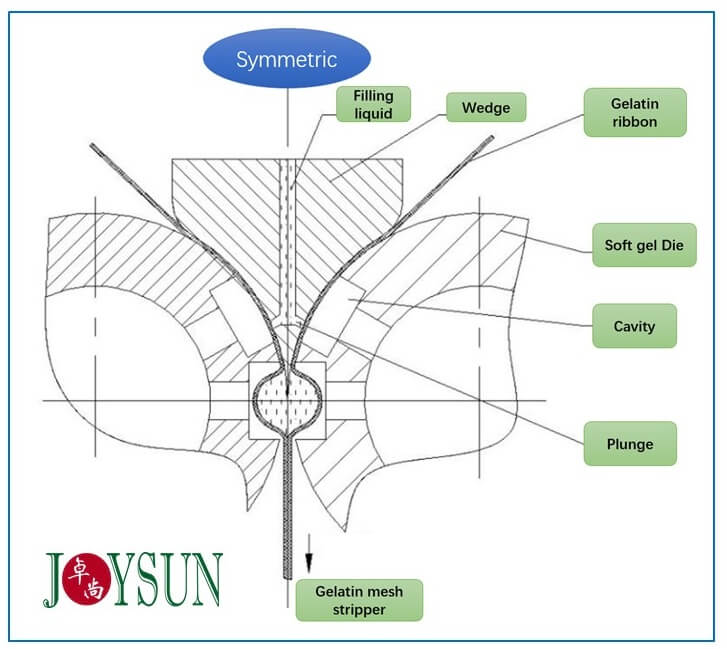

When you install a new set softgel mold, pay important matter to the symmetry of the 2 dies. They must match each other upon the line/groove cut on the dies. And match the line on dies with the line on the wedge. After matching the lines, there is injection time. Be sure of an injection time, otherwise, the filling medicine might shoot out of softgel into gelatin, or shoot on the die surface, making the machine dirty and oily everywhere. Below photos can guide users to a correct die roll and wedge matching. Synchronization matters greatly. Whether the injection pump, wedge, and mold cavity are synchronized, if a little bit deviates, will also cause leakage.

4. The improper design of cavities size, mainly is a smaller size while to fill too much oil.

Gelatin ribbon does have a certain expansion rate to hold more oil than it should. But users should not overfill. E.G. the die is supposed to fill 500mg of oil, the operator tries to fill more such as 600mg, 700mg. after softgel dried and shrinked, there might be leakage. This happens quite often in suspension-type softgel. The softgel machine user doesn’t know how to calculate the best size for paste suspension softgel. Please be aware that the cavity size design math for oil and for suspension is different.

5. Softgel leakage happens during the storage period.

This mostly relates to the formula of softgel. As in some softgel filling, the medicine contains PEG (such as Ibuprofen softgel). When there is too much PEG in the recipe, during the storage, the PEG might suck water into the gelatin shell, making the shell crispy and easy to break.

6. There are also some causes non-softgel encapsulation machine-related.

To make softgel capsules, there is strict temperature and humidity requirement for the encapsulation room, and drying room. Too high temperature and too high relative humidity can affect gelatin seam, so lead to leakage.

7. The gelatin powder and the gelatin solution performance matter.

The low viscosity of the gelatin mass might lead to softgel oil leakage. When the softgel encapsulation machine runs at a relatively fast speed, the moisture of the gelatin solution is high, not enough time, and not easy to evaporate water via the cooling drum and fan. Then after encapsulation, the softgel enters the drying process, and too much water is left causing a leak gradually.

Low viscosity also results in poor adhesive ability, such as a poor seam. We suggest gelatin powder bloom at least ≥150lb, and should buy from reliable suppliers. The proportion among water, gelatin powder, and glycerin; the final water content in gelatin mass after melting matter.

However, a too viscous gelatin solution might fail to carry out a good sealing too. Bad seaming finally ends up softgel leaking. Because die roll is difficult to cut gelatin ribbon off. Therefore, the operator should have a standard checking for the gelatin solution.

The gelatin melting process should be well and strictly controlled and carried out. An SOP (Standard Operating Procedure) for gelatin melting is strongly suggested.

To make fish oil≈17000cps after gelatin melting is done, relatively dilute

Q10, Propolis, and other suspension soft capsules about≈21000-22000 cps

Lecithin is harder to encapsulate, about≈25000cps is suggested

Softgel manufacturing is complicated as a good softgel encapsulation machine is just the most basic requirement for this line. The proper operation, recipe, formulation, temperature, humidity control, raw material quality and etc. also matter. So it is very important to have a professional team to support. Welcome to contact us for inquiry.