Description

Softgel Encapsulation Machine

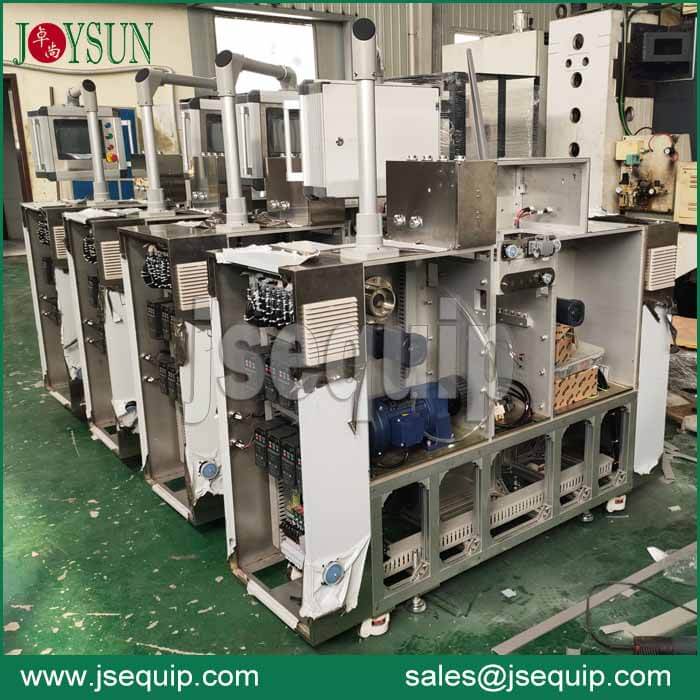

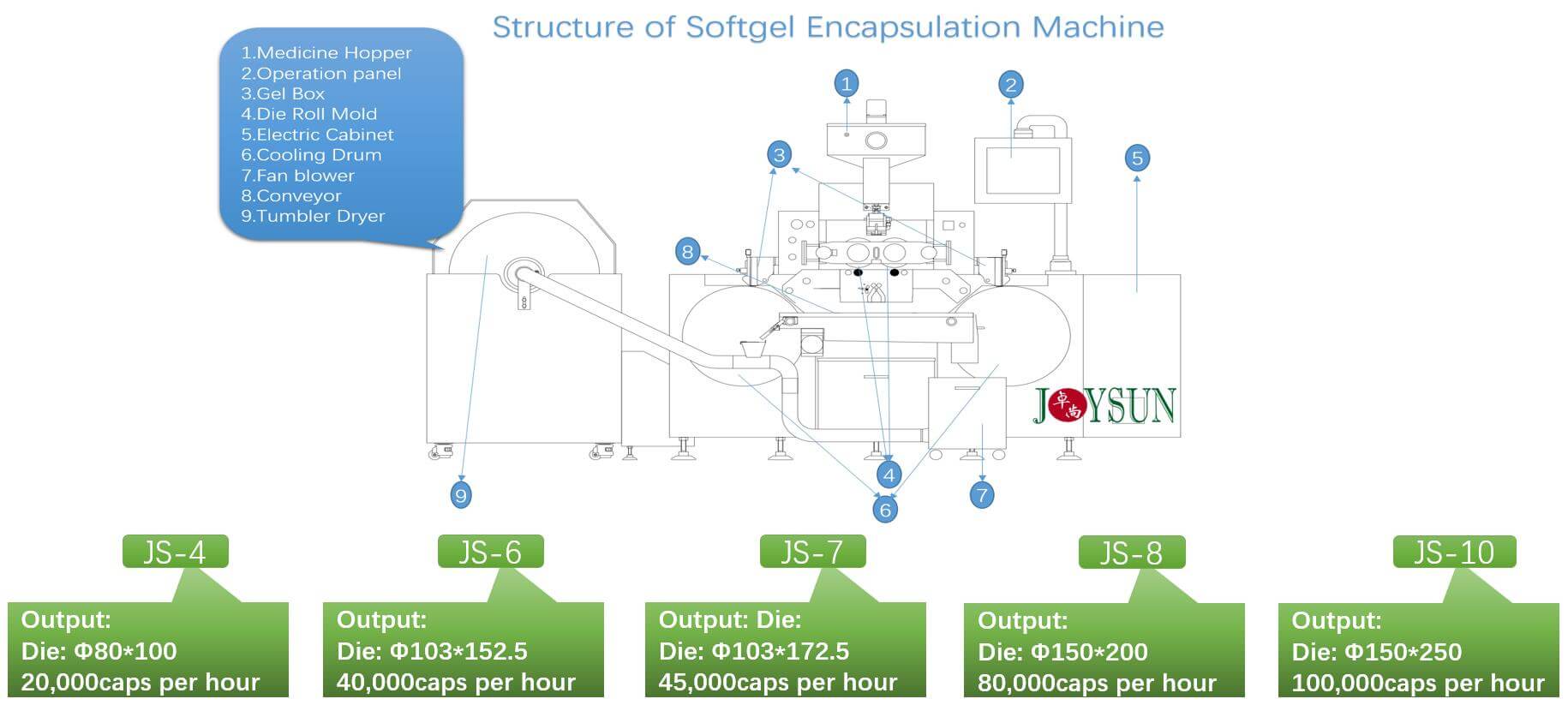

A series of softgel encapsulation machine models are available for options. Range from lab size, medium size to mass production scale.

JS-4: 20K capsules per hour based on 500mg Oval fish oil soft gelatin; Best choice for small-scale production.

JS-6 and JS-7 model: Output per hour: 40k-45k per hour, are good for middle scale softgel production.

JS-8 and JS-10: Yield per hour: 80K-100K fish oil softgel of 8# Oval for mass production factories.

Chinese Softgel Encapsulation Machine Characteristics

JS series softgel capsule machine runs stably for a continuous 24hours, 7days per week, all year round with very stable working conditions.

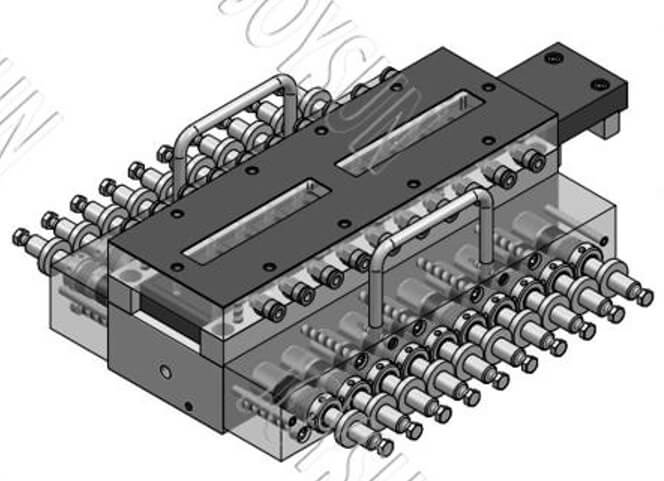

Plunger precisely filling into mold cavities, accurate soft gelatin weight. Three types of plungers for options such as100-250mg, 250-1000mg, and>1000mg. For pharmaceutical softgel it is very important to control a small and precise filling accuracy. Users can either choose to have a set of a standard 0-2ml plunger for all products or change the plunger to suit different filling dosage capsules.

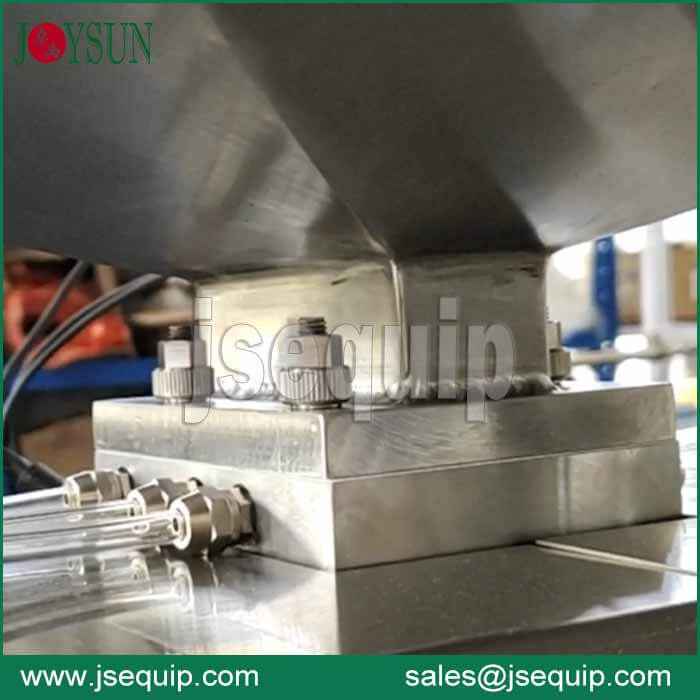

V-type polytetrafluoroethylene(PTFE) sealing ring inside the injection pump, more accurate than the regular O-type seal.

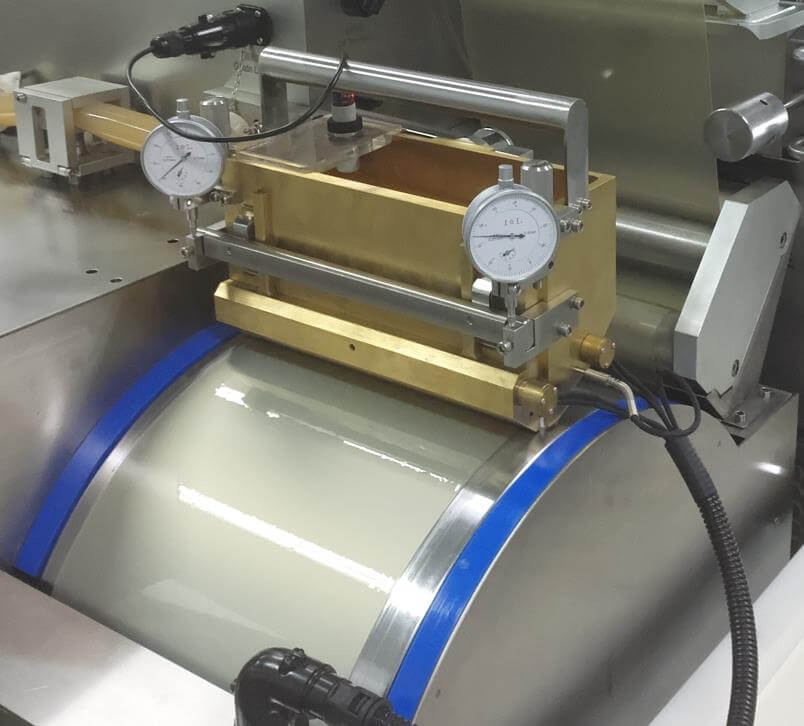

Automatic Gelatin ribbon thickness adjustment is an option.

Gelatin ribbon width is also adjustable to fully cover the die roll surface.

Imported Japan brand medicine filling pump is used to transfer material, precise and sanitary.

Touch screen and PLC make all settings and operations easier.

The whole Machine is made of an aluminum frame with 304 covers, the contact part material is 316L.

Lubrication System: Micro lubrication, reduce the conventional too oily situation. Reducing paraffin oil consumption and saving costs.

Dies Symmetry: Parallelism≤0.02mm; reduces operation failure.

Ultra-High accuracy temperature control;

Extremely low gelatin wastage;

Ultra-high precision cooling drum: water cooling instead of conventional machine fan cooling.

Independent capsule stripper has driven: gelatin ribbon peels off easily.

Independent mangle roller drove: easier adjustment and fine-tuning.

Automatic hopper level control: easy checking the filling material inside. With capsule accumulation counter.

| JS-10 Machine Production Capacity for Different Dies More molds need to order extra, machine with one full set mold |

|||||

| Size | Shape |

Capsules per round | Capacity (@3.5rpm) | Capacity (@4rpm) | |

| 3 | OVAL | 697 | 146370 | 167280 | |

| 6 | 532 | 111720 | 127680 | ||

| 7.5 | 455 | 95550 | 109200 | ||

| 10 | 442 | 92820 | 106080 | ||

| 14 | 372 | 78120 | 89280 | ||

| 6 | OBLONG | 506 | 106260 | 121440 | |

| 16 | 304 | 63840 | 72960 | ||

| 20 | 252 | 52920 | 60480 | ||

| 2 | ROUND | 740 | 155400 | 177600 | |

| 5 | 594 | 124740 | 142560 | ||

| Note: the speed of machine and exact filling qty largely depends on user’s operation and softgel types. Above is a reference list, might differ during actual production. | |||||

| JS-4 Machine Production Capacity for Different Dies More molds need to order extra, machine with one full set mold |

|||||

| Size | Shape | Capsules per round | Capacity (@3.5rpm) | Capacity (@4rpm) | |

| 2 | OVAL |  |

161 | 33810 | 38640 |

| 3 | 132 | 27720 | 31680 | ||

| 4 | 105 | 22050 | 25200 | ||

| 5 | 100 | 21000 | 24000 | ||

| 6 | 95 | 19950 | 22800 | ||

| 8 | 95 | 19950 | 22800 | ||

| 10 | 72 | 15120 | 17280 | ||

| 12 | 72 | 15120 | 17280 | ||

| 6 | OBLONG |  |

96 | 20160 | 23040 |

| 8 | 92 | 19320 | 22080 | ||

| 10 | 66 | 13860 | 15840 | ||

| 12 | 63 | 13230 | 15120 | ||

| 14 | 60 | 12600 | 14400 | ||

| 16 | 60 | 12600 | 14400 | ||

| 18 | 57 | 11970 | 13680 | ||

| 20 | 38 | 7980 | 9120 | ||

| 22 | 36 | 7560 | 8640 | ||

| 24 | 34 | 7140 | 8160 | ||

| Note: the speed of machine and exact filling qty largely depends on user’s operation and softgel types. Above is a reference list, might differ during actual production. | |||||